UV vs. IR Grade Fused Silica

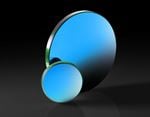

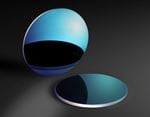

Fused silica is a common glass type used in the optics industry to manufacture optical components such as lenses, windows, mirrors, prisms, and beamsplitters. Fused silica is often a preferred material for precision optics due to its consistent and repeatable optical performance.1 Additionally, fused silica demonstrates a low thermal expansion coefficient that provides high thermal stability and resistance to thermal shocks, which are often critical characteristics in specific applications. Fused silica also has a high chemical resistance and minimal fluorescence. There are many types of fused silica, the most common include UV grade fused silica and IR grade fused silica.

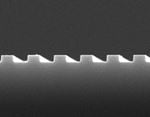

UV grade fused silica is manufactured synthetically through the oxidation of high purity silicon by flame hydrolysis.2 The UV grade demonstrates high transmittance in the UV spectrum, but there are dips in transmission centered at 1.4µm, 2.2µm, and 2.7µm due to absorption from hydroxide (OH-) ion impurities.

IR grade fused silica differs from UV grade fused silica by its reduced amount of OH- ions, resulting in higher transmission throughout the NIR spectrum and reduction of transmission in the UV spectrum (Figure 1). OH- ions can be reduced by melting high-quality quartz or using special manufacturing techniques.3

Figure 1: Transmission data for UV and IR grade fused silica for a 5mm thick sample without Fresnel reflections1

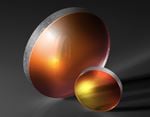

Developments in lasers with wavelengths around 2µm, including thulium (2080nm) and holmium (2100nm), have led to many more applications utilizing lasers in the 2µm wavelength region. 2µm is close to one of the OH- absorption peaks in UV grade fused silica, making IR grade fused silica a much better option for 2µm applications. The high absorption of UV grade used silica around 2µm will lead to heat generation and potentially cause damage. However, IR grade fused silica optical components often have a higher cost and lower availability.

Understanding your application’s wavelength range is important for selecting the appropriate substrate. Edmund Optics® offers select optical components with IR grade fused silica (Corning 7979) and UV grade fused silica (Corning 7980) substrate options. For assistance in selecting the correct fused silica product for your application, please contact our free engineering support.

Download Corning Fused Silica Data Sheet

References

- “Corning HPFS® 7979, 7980, 8655 Fused Silica.” Corning, February 2014.

- Linow, Sven, et al. “Experimental Study of the Synthesis of Fused Silica by Direct Combustion Hydrolysis.” Experiments in Fluids, vol. 32, no. 1, Jan. 2002, pp. 66–75., doi:10.1007/s003480200007.

- Nürnberg, Frank, et al. “IR Grade Fused Silica for High-Power Laser Applications.” ICOL, Mar. 2014, doi:10.13140/2.1.2604.8007.

或查看各区域电话

报价工具

只需输入商品编号

Copyright 2023, 爱特蒙特光学(深圳)有限公司。— 广东省深圳市龙华工业东路利金城科技工业园3栋5楼 518109 - 粤ICP备2021068591号